組成

常見的pt1000感溫元件有陶瓷元件,玻璃元件,雲母元件,它們是由鉑絲分別繞在陶瓷骨架,玻璃骨架,雲母骨架上再經過複雜的工藝加工而成

套用

醫療、電機、工業、溫度計算、阻值計算等高精溫度設備,套用範圍非常之廣泛。

PT1000分度表

| | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 100 | 1385.055 | 1388.847 | 1392.638 | 1396.428 | 1400.217 | 1404.005 | 1407.791 | 1411.576 | 1415.360 | 1419.143 |

| 110 | 1422.925 | 1426.706 | 1430.485 | 1434.264 | 1438.041 | 1441.817 | 1445.592 | 1449.366 | 1453.138 | 1456.910 |

| 120 | 1460.680 | 1464.449 | 1468.217 | 1471.984 | 1475.750 | 1479.514 | 1483.277 | 1487.040 | 1490.801 | 1494.561 |

| 130 | 1498.319 | 1502.077 | 1505.833 | 1509.589 | 1513.343 | 1517.096 | 1520.847 | 1524.598 | 1528.381 | 1532.139 |

| 140 | 1535.843 | 1539.589 | 1543.334 | 1547.078 | 1550.820 | 1554.562 | 1558.302 | 1562.041 | 1565.779 | 1569.516 |

| 150 | 1573.251 | 1576.986 | 1580.719 | 1584.451 | 1588.182 | 1591.912 | 1595.641 | 1599.368 | 1603.094 | 1606.820 |

| 160 | 1610.544 | 1614.267 | 1617.989 | 1621.709 | 1625.429 | 1629.147 | 1632.864 | 1636.580 | 1640.295 | 1644.009 |

| 170 | 1647.721 | 1651.433 | 1655.143 | 1658.852 | 1662.560 | 1666.267 | 1669.972 | 1673.677 | 1677.380 | 1681.082 |

| 180 | 1684.783 | 1688.483 | 1692.181 | 1695.879 | 1699.575 | 1703.271 | 1706.965 | 1710.658 | 1714.349 | 1718.040 |

| 190 | 1721.729 | 1725.418 | 1729.105 | 1732.791 | 1736.475 | 1740.159 | 1743.842 | 1747.523 | 1751.203 | 1754.882 |

| 200 | 1758.560 | 1762.237 | 1765.912 | 1769.587 | 1773.260 | 1776.932 | 1780.603 | 1784.273 | 1787.941 | 1791.610 |

| 210 | 1795.275 | 1798.940 | 1802.604 | 1806.267 | 1809.929 | 1813.590 | 1817.249 | 1820.907 | 1824.564 | 1828.220 |

| 220 | 1831.875 | 1835.529 | 1839.181 | 1842.832 | 1846.483 | 1850.132 | 1853.779 | 1857.426 | 1861.072 | 1864.716 |

| 230 | 1868.359 | 1872.001 | 1875.642 | 1879.282 | 1882.921 | 1886.558 | 1890.194 | 1893.830 | 1897.463 | 1901.096 |

| 240 | 1904.728 | 1908.359 | 1911.988 | 1915.616 | 1919.243 | 1922.869 | 1926.494 | 1930.117 | 1933.740 | 1937.361 |

| 250 | 1940.981 | 1944.600 | 1948.218 | 1951.835 | 1955.450 | 1959.065 | 1962.678 | 1966.290 | 1969.901 | 1973.510 |

| 260 | 1977.119 | 1980.726 | 1984.333 | 1987.938 | 1991.542 | 1995.145 | 1998.746 | 2002.347 | 2005.946 | 2009.544 |

| 270 | 2013.141 | 2016.737 | 2020.332 | 2023.925 | 2027.518 | 2031.109 | 2034.699 | 2038.288 | 2041.876 | 2045.463 |

| 280 | 2049.048 | 2052.632 | 2056.215 | 2059.798 | 2063.378 | 2066.958 | 2070.537 | 2074.114 | 2077.690 | 2081.265 |

| 290 | 2084.839 | 2088.412 | 2091.984 | 2095.554 | 2099.123 | 2102.692 | 2106.259 | 2109.824 | 2113.389 | 2116.953 |

| 300 | 2120.515 | | | | | | | | | |

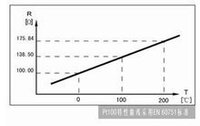

圖表

PT100/PT1000鉑電阻RT曲線圖表

PT100/PT1000鉑電阻RT曲線圖表

PT100/PT1000鉑電阻RT曲線圖表參數

薄膜鉑電阻:用真空沉積的薄膜技術把鉑濺射在陶瓷基片上,膜厚在2微米以內,用玻璃燒結料把Ni(或Pd)引線固定,經雷射調阻製成薄膜元件。技術指標:溫度係數:TCR=3850ppm/K溫度範圍:B級:-70℃-500℃A級:-50℃-300℃1/3DIN:0---150°C引腳材質:鉑鎳合金,規範:DINEN60751(符合IEC751)尺寸:2.3mm×2.1mm×0.9mm(長×寬×高)引腳長10mm長期穩定性:R0漂移小於等於0.04%(500℃,1000小時後)抗振動等級:至少40g加速度(10-2000Hz)絕緣電阻:>100MΩ,20℃時>2MΩ,500℃時抗衝擊等級:至少100g加速度(波動8.5mS後)自熱係數:0.4K/mW(0℃時)回響時間:水@0.4m/st0.5=0.05St0.9=0.15S空氣@2m/st0.5=3.0St0.9=10.0S環境條件:未保護時只能用於乾燥環境,測量電流:PT100:0.3-最大1.0mA,PT1000:0.1至0.3mA