概述

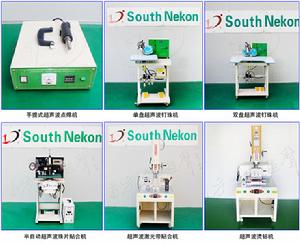

國內最早生產超音波釘珠機的企業,經過不斷的研發、設計,現已開發出力勁第二代單、雙盤釘珠機。釘珠速度達到每分鐘150粒,比同行業類型機器提高30%釘珠速度,更有自主設計研發的珠盤亞克力護罩,

超音波釘珠機-燙鑽機-珠片機

超音波釘珠機-燙鑽機-珠片機工作原理:通過本機的電子線路系統把220V/50HZ的交流電轉換為35KHZ的交流電,再通過換能器轉換為機械能的振動。超音波釘珠機的原理就是先把鑽石壓在超音波焊頭上,再由焊頭髮出機械能的振動,壓

在上面的鑽石經下面的機械振動後把上面的熱熔膠熔化,最終粘在布料或皮料上。

超音波釘珠機又稱超音波釘鑽機/超音波點鑽機/飾品點鑽機/服裝點鑽機/牛仔褲點鑽機/ 婚紗點鑽機/自動釘珠機/釘鑽機/超音波鑲鑽機/超音波燙圖機/超音波整版燙/鞋麵點鑽機/釘鑽機/鑲鑽機/燙圖機/鑽石手動貼上機/焊鑽機。

技術參數

電源電壓:220V/50-60HZ

超音波釘珠機

超音波釘珠機超音波消耗功率:200W

工作氣壓:0.6-0.8Mps

工作類型:超音波

機器重量:56KG

機器尺寸:800*600*1100(L*W*H)

效 率: 130-150粒/分鐘

功能與特點

1.超音波釘珠機能通過超音波使珠子立即固定於物料(絲絨、牛仔布、針織布、Pu布、真皮以及其他合成革)上。

2.超音波釘珠機套用於鞋類燙鑽、內衣、童裝、T恤、繡花圖案、皮革、手袋、髮飾、帽及其他飾品上。

3.超音波釘珠機加工效率極高,可完成130-150粒/分鐘。

4. 色彩多變、定位準確,珠片貼合牢固、工藝精美、不傷輔料

5. 適用在圖案不規則的珠片裝飾工藝。更省工人,工時,加工成本更加低廉

套用行業

廣泛套用於服裝(婚紗、童裝)、帽業、飾品等諸多行業。

釘珠樣板

釘珠樣板超音波釘珠機使用說明書

簡介東莞市南方力勁機械有限公司是國內最早生產超音波釘珠機的企業,經過公司不斷的研發、設計,現已開發出力勁第二代單、雙盤釘珠機。釘珠速度達到每分鐘150粒,比同行業類型機器提高30%釘珠速度,更有南方力勁自主設計研發的珠盤亞克力護罩,防止鑽石在加工過程中跳珠盤散落,避免造成浪費,節約了成本。

工作原理:通過本機的電子線路系統把220V/50HZ的交流電轉換為35KHZ的交流電,再通過換能器轉換為機械能的振動。超音波釘珠機的原理就是先把鑽石壓在超音波焊頭上,再由焊頭髮出機械能的振動,壓在上面的鑽石經下面的機械振動後把上面的熱熔膠熔化,最終粘在布料或皮料上。

超音波釘珠機又稱超音波釘鑽機/超音波點鑽機/飾品點鑽機/服裝點鑽機/牛仔褲點鑽機/婚紗點鑽機/自動釘珠機/釘鑽機/超音波鑲鑽機/超音波燙圖機/超音波整版燙/鞋麵點鑽機/釘鑽機/鑲鑽機/燙圖機/鑽石手動貼上機/焊鑽機。

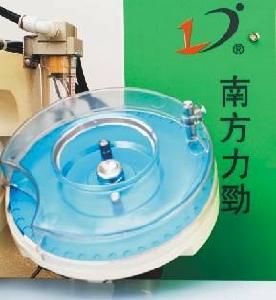

理珠裝置,珠盤添加亞克力防護罩,防止鑽石調出珠盤散落,造成浪費。

單盤裝置

單盤裝置 雙盤裝置

雙盤裝置 理珠裝置新型專利證書

理珠裝置新型專利證書 理珠裝置外觀設計證書

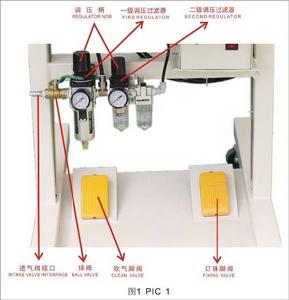

理珠裝置外觀設計證書第一步:接通氣源,即將外部氣源接在如下圖所示的“進氣閥接口”上,同時鏇開“球閥”(如圖1所示)。

圖1

圖1第二步:調節工作氣體的壓力,即依次鏇動如上圖1所示的“一級調壓過濾器”和“二級調壓過濾器”,使“一級調壓過濾器”的壓力表指針指在0.3MPa-0.4MPa之間,使“二級調壓過濾器”的壓力表的指針指在0.2MPa~0.4Mpa之間,方法如下:

Adjust the air pressure, turn the FIRST REGULATOR and the SECOND REGULATOR, so that the First Air Pressure metre reads between 0.3MPa-0.4MPa,and the Second Air Pressure Metre reads between 0.2MPa~0.4Mpa as indicated below:

1. 用手捏住調壓過濾器的調壓柄(如圖1所示露出的部分),向外拉使調壓柄脫離固定齒,此時即可向順時針或逆時針方向鏇動調壓柄,同時可以看到壓力表的指針跟著轉動,即順時針鏇動調壓柄,氣壓增加,逆時針鏇動調壓柄,氣壓減小;

Pull out the REGULATOR nob(as shown in PIC 1)and turn it either way round, and the needle will go up or down, turning the REGULATOR NOB clockwise will increase the air pressure and anti-clockwise decreases the air pressure.

2.調好壓力後將調壓柄向里推,使固定齒將調壓柄固定。

Push back the REGULATOR NOB when the air pressure is correctly set.

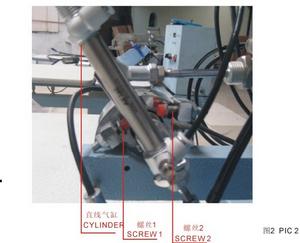

第三步:擺動角度和方位。

Adjust the swing angle and position of the CILIDER

鏇開“螺絲1”和“螺絲2”(如圖2所示),然後手持直線氣缸(如圖2所示),此時可以發現擺動氣缸可以

圖2

圖2Loosen SCREW 1 and SCREW 2(as shown in PIC 2), hold the CYLINDER by hand, and now the CYLINDER is free for swinging, swing the CYLINDER to the down position (make sure that it points to the Ultra-Sound Head) and Fasten SCREW 1,then swing the CYLINDER to the position that it stands 90 degrees with the disk(as shown in PIC 4,and make sure that the muzzle points to the Sink for the stone and fasten SCREW2.Now the CYLINDER position is settled. If the position is a little right or left, loosen ADJUSTING SCREW and turn the ADJUSTING NUT with a screw driver (cross)(as shown in PIC 3),and then fasten the ADJUSTING SCREW.

圖3

圖3 圖4

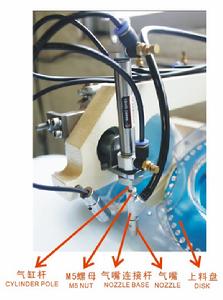

圖4Adjust the spacing between NOZZLE and DISK

用扳手夾住“氣嘴連線件”,然後鏇開“M6螺母”,再通過鏇動“氣缸桿”即可改變“氣嘴”與“上料盤”之間的距離,調到想要的距離後,再夾住“氣嘴連線件”,然後將“M6螺母”鎖緊即可,“氣嘴”與“上料盤”之間的距離調節的依據為:“氣嘴”與燙鑽的頂面為1-2mm之間,較大的燙鑽兩者之間的距離要求大一點(較大的燙鑽所配的氣嘴中心孔也較大)。

Hold the NOZZLE BASE with a spanner ,loosen M6 NUT ,and the spacing between the NOZZLE and the DISK can be adjusted by turning the CYLINDER POLE, when the spacing is set correctly, fasten the M6 NUT. Usually, the spacing can be set so that the NOZZLE is 1-2MM from the stone, and larger stones require a little bigger spacing (and the size of the NOZZLE should also be bigger).

第五步:調節面板上的按鈕和鏇鈕

Adjust the buttons and knobs on the control Panel

1.按鈕說明及調節

Knobs adjustment

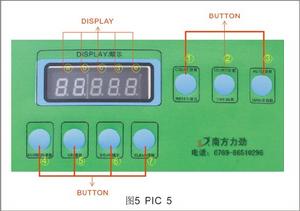

a) 當接通電源時,在b, c, d, e處分別顯示“A”“u”“t”“o”,表示機器處於“自動狀態”,此時如果按一下“按鈕03”,在a,b,d,d,e處全部顯示“0”,表示機器處於“非自動狀態”。在“自動狀態”時,用腳踏住右腳踏開關不鬆開,此時機器就連續的工作;在“非自動狀態”時,用腳踏住右腳踏開關,機器卻不能連續工作,只能點動一次才能工作一次。

When powering on the machine ,if in the indicators b ,c, d, e show Auto, the machine is set to work automatically, and when PEDAL SWITCH R is pressed down, the machine works continuously. If BUTTON 03 is pressed, the indicators a ,b, c, d, e, all show 0,the machine is set to work manually, each press on the PEDAL SWITCH R will get the machine pick one stone for the sticking(as shown in PIC 5).

圖5

圖5Press BUTTON04, a digit between 0-7 will be displayed in indicator a, it indicates a parameter ,there will be n display on indicator b, while in indicators c, d, and e display the value of this parameter. For instance, a display of 1 101 means that the first parameter is set 10for its value; and if the display of 5 006 means that the value of the fifth parameter if set as 6.

此時如果要使某號參數數值增加(Up),按住按鈕05,該數值就能夠從0增加到255之間的任一數值(最大為255)此時如果要使某號參數的數值減小(Down),按住按鈕06,該數值就可減小到0

To set the value of a certain parameter higher, press BUTTON 05, the value goes up till it reaches 255 as the maximum , to set the value smaller, Press BUTTON 06,and the value goes down till 0 as the minimum.

c) 機器處於“非自動狀態”是,可以顯示機器自動記錄的工作次數,工作次數顯示在“a”“b”“c”“d”“e”處,如00100,機器工作100次,理論上可以焊合100顆人造鑽石。

When the machine is in a state of MANUAL WORK, the indicators display the counting of the work. A display of 00100 indicates that the machine has worked 100 times, and thus 100 stones has been stuck on the fabric.

此時按一次按鈕01,就將顯示的數據復位到0

A press on Button 01 will reset the value back to 0.

此時按一次按鈕02,就可以在“a”“b”“c”“d”“e”處一次顯示設定好的0-7的參數號及相應的參數值(一閃而過),最後顯示機器的工作次數。

A press on BUTTON 02 will set the indicators display the setting of the parameters from 0 to 7 one by one.

d)按一下“按鈕07”,此時直線氣缸將處於垂直狀態,同時氣嘴不斷的噴氣,目的是噴出氣路里的雜物,按“按鈕07”與踩左腳踏開關具有相同的效果。

A press on BUTTON 07 will set the NOZZLE vertical and release the compressed air so that the dust or bits of broken stones will be blown out from the NOZZLE, it has the same function as the PEDAL SWITCHL.

2.鏇鈕說明及條件

Adjustment on KNOBS

圖6

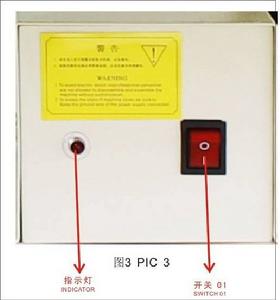

圖6SEITCH 02 works for the shifting between the two disks, there is the marking of LEFT and RIGHT below SWITCH 02 indicating the position of the SEITCH.SWITCH 03 works as the main power switch (as shown in PIC 6).SWITCH 01 works as the ultra-sonic switch. We need to Turn on SWITCH 01 first(as shown in PIC 3)and then turn on SWITCH 03 and enable the ultra-sonic device to start working.

當打開電源就可以看到布料上有一個紅光點,該光點即為紅雷射指示,用來指示在布料上所要燙焊的位置,鏇轉“鏇鈕01”,就可以調節紅光點的強弱,以適應各種顏色的布料,逆時針鏇光點變強,順時針鏇轉,光點變弱。

When the power is on ,there will be a small red light point on the fabric indicating the target position for the stone, turn KNOB 01 for the strength of the red light; anti-clockwise gets the red light brighter and clockwise gets the red light dimmer.

鏇轉“按鈕02”即可以調劑電機電流的大小,從而調節上料盤的轉速,即當氣嘴只吸取部分人造鑽石時,表示上料盤的轉速太快,此時順時針鏇轉“鏇鈕02”,當吸嘴等待一下才開始吸取下一個人造鑽石,表示轉速太小,此時向“逆時針”方向調節“按鈕02”,直到吸嘴將所有轉過來的人造鑽石全部吸掉,同時吸嘴不等待,此時轉速最佳。

KNOB 02 is used for adjustment on the motor so that we can adjust the rotation speed of the disks, If the NOZZLE misses some of the stones, the rotation speed is set too high, turn KNOB 02 clockwise to lower the speed. If the NOZZLE waits for the stones now and then, the speed id set too low, turn KNBO 02 anti-clockwise to raise the speed.

當氣嘴沒有吸到燙鑽,擺動氣缸也作出擺動的動作,此時需要將“鏇鈕03”向逆時針方向鏇動,當氣嘴將人造鑽石吸住後,擺動氣缸也不擺動,此時將“鏇鈕03”向順時針方向鏇動,當氣嘴將燙鑽吸住後就擺下,在上料盤沒鑽時,氣嘴等待,直到將鑽石吸住,才擺下,此時鏇鈕的位置即為正常狀態。(註:當氣壓和焊合的燙鑽規格發化,該鏇鈕即要重新調節生變化,該鏇鈕即要重新調節)

If the NOZZLE swings without sucking up a stone, turn KNBO 03 anti-clockwise so that the compressed air is stronger. If the NOZZLE does not swing after sucking up a stone, turn KNOB 03 clockwise so that the compressed air is weaker. (If the compressed air pressure or the size of the stones if changed, usually we need to readjust KNOB 03, till the NOZZLE picks every stone on the disk).二、0-7號8個參數功能Parameter Setting

0號參數:腳踏開關打開到氣嘴開始吸氣之間的間隔時間,此參數的意義在於讓氣嘴有充分的準備,一般調為1;

Parameter 0: the timing between the pressing on PEDAL SWITCH L and the working of NOZZLE, this parameter is set so that the NOZZLE has some time for the preparation for the work. Usually, the value of this parameter is set 1.

1號參數:擺動氣缸開始動作到直線氣缸開始動作之間的間隔時間,此參數的意義在於讓擺動氣缸擺到一定的位置時,直線氣缸才開始帶著氣嘴連同鑽石下壓焊合,這樣可以控制氣嘴向前的慣性,讓焊合的位置更加準確,一般調為3-6;

Parameter 1: the timing of the Cylinders swinging between starting and the end, The parameter setting is to control the movement of the Cylinder so that it goes to the correst positon without any over movement, thus place the stones correctly to the fabric for the sticking. Usually, the parameter is set from 3 to 6.

2號參數:直線氣缸從壓下到回縮之間的間隔時間,一般調為1-3;

Parameter 2: the timing between the NOZZLE going down and up. Usually set between 1 to 3

3號參數:超音波加熱的時間,薄布料小燙鑽,要將此值調低,厚布大燙鑽,要將此值調高,一般為15-35;

Parameter 3: the timing of the ultra-sonic device heating, thinner fabric requires a lower value while thick fabric requires higher value. It is usually set from 15 to 35.

4號參數:氣嘴吹氣的時間,一般調為1-2即可;

Parameter 4: the timing for the NOZZLE to release compressed air for cleaning, it is usually set from 1 to 2.

5號參數:直線氣缸開始回縮到擺動氣缸回擺之間的間隔時間,一般調為3-5;

Parameter 5: the timing between the NOZZLE Cylinders retreating movement and the movement of the swinging Cylinder. Usually set from 3 to 5.

6號參數:兩個工作周期之間的間隔時間,一般調為0-3;

Parameter 6: the timing between two complete work round. Usually set from 0 to 3.

7號參數:平衡吸嘴的時間,一般調為1-5.

Parameter 7: the timing for the balance of the NOZZLE. Usually set from 1 to 5.

故障1:人造鑽石在布料上被壓碎 Stones broken on fabric

圖7

圖7Turn the SPEED CONTROL 1-2 clockwise to reduce the pressure to the stones from the NOZZLE (as shown in PIC 7)

在超音波加熱頭上放上柔質的東西;

Places something soft to the NOZZLE.

故障2:氣嘴在吸取時碰到人造鑽石頂部

NOZZLE presses too much on stones and damages the stone surface.

氣嘴距上料盤的距離太小,根據第四步,調節氣嘴與上料盤之間的距離,將兩者的距離調大一點即可解決。

The spacing between the NOZZLE and the disk is too small, Reset the spacing as per Adjust the spacing between NOZZLE and DISK.

故障3:氣嘴雖吸住人造鑽石,但在擺動氣缸回擺時,落下

Stones fall down during the swinging of the CYLINDER.

氣嘴距上料盤的距離太大,根據第四步,調節氣嘴與上料盤之間的距離,將氣嘴與上料盤的距離調小一點即可。

The spacing between the NOZZLE and the disk is too large. Reset the spacing as per Adjust the spacing between NOZZLE and DISK.

故障4:擺動氣缸在下擺時,氣嘴碰到上料盤

The SWING BYLINDER touches the disk when swinging down.

將1號參數調大

Reset Parameter 1 to a bigger value.

圖8

圖8Turn SPEED CONTROL 2-1 clock-wise as shown in PIC 8.

故障5:擺動氣缸在回擺時,氣嘴碰到上料盤

The SWING CYLINDER touches the disk when swinging up.

將5號參數調大

Reset Parameter 5 to a bigger value.

將“節流閥2-2”的調節鏇鈕向順時針方向慢慢鏇動,(見圖8)。

Turn SPEED CONTROL 2-2 clock-wise as shown in PIC 8.

故障6:人造鑽石不能夠牢固的焊合在布料上

Stones are not firmly stuck on the fabric

將“節流閥1-2”的調節鏇鈕向逆時針方向鏇動,(見圖7)

Turn SPEED CONTROL 1-2 anti-clock-wise as shown in PIC 7.

將3號參數調大

Reset Parameter 3 to a bigger value.